Mochine oa Wheat Semolina Flour Plansifter

Mochini oa ho sefa

Letoto la FSFG planifter ke e 'ngoe ea lihlahisoa tsa rona tsa mantlha tse ntlafalitsoeng motheong oa mehopolo e ncha.E khona ho sefa hantle le ho hlophisa lisebelisoa tsa granular le pulverulent.Joalo ka mochini oa ho hlopha phofo ea premium, e loketse baetsi ba phofo ba sebetsang koro, raese, koro ea durum, rye, oat, poone, buckwheat, joalo-joalo.Ha e le hantle, mofuta ona oa sifter ea leloala e sebelisoa haholo-holo bakeng sa ho lokisa koro e sililoeng le ho sefa thepa e bohareng, hape le ho sefa ho hlahloba phofo.Meetso e fapaneng ea sieving e lumellana le liphaseje tse fapaneng tsa ho sefa le lisebelisoa tse mahareng.

Molao-motheo oa ho sebetsa

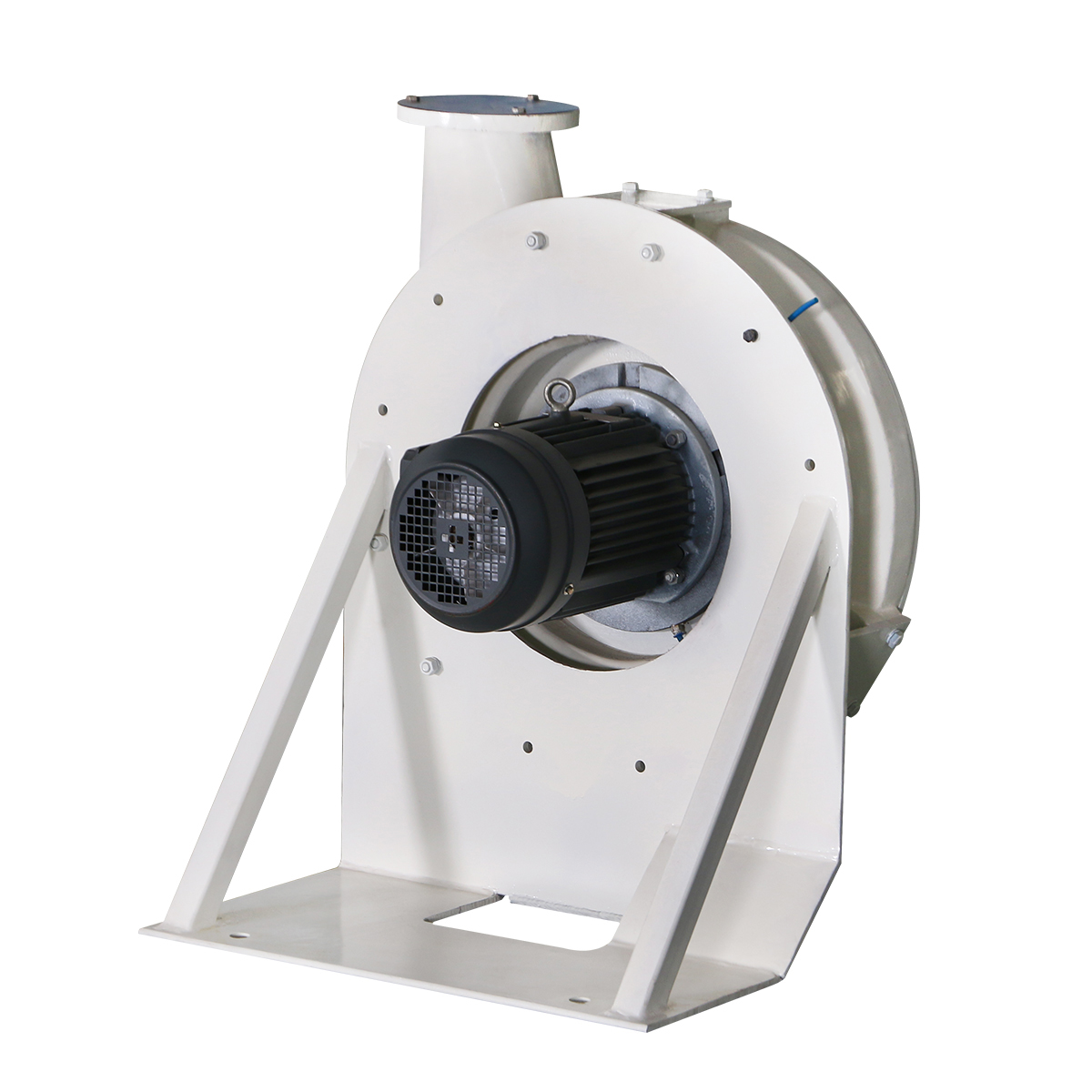

Mochini o khannoa ke enjene e kentsoeng ka har'a foreimi e kholo 'me e leka-lekana ka counterweight.Mochine o mong le o mong o na le likarolo tse 4, kapa tse 6, kapa tse 8 ka hare.Lintho tse fapaneng li phalla karolong e fapaneng ka tsela ea eona.Ho ea ka moralo oa motho ka mong bakeng sa lisebelisoa tse fapaneng, sieve e sefa lisebelisoa tse fapaneng tsa granular ho ea ho tse ling tse latelang liloaleng tsa phofo ha mochini oohle o ntse o sebetsa.

Sebopeho

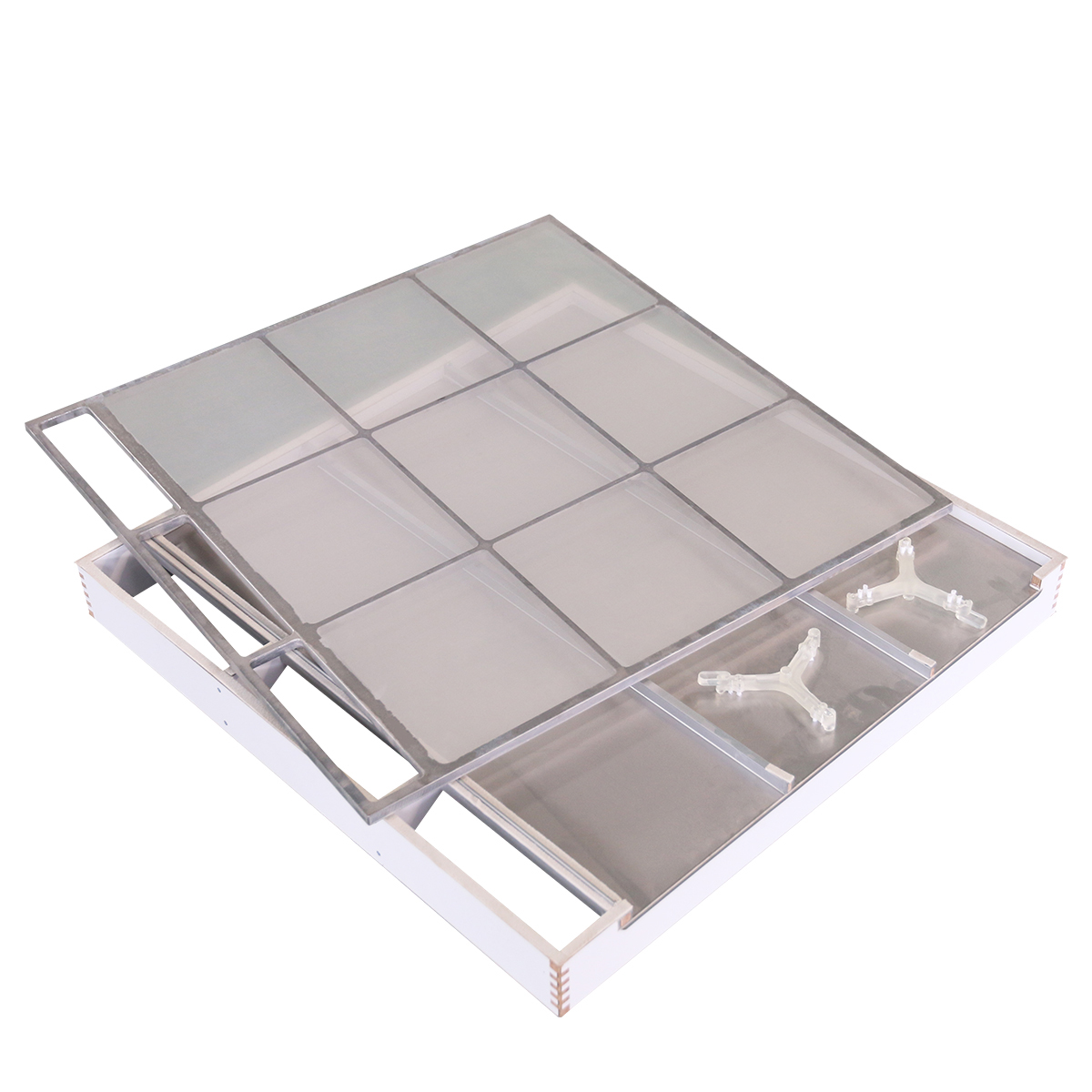

1. Boholo ba foreimi ea sieve bo fumaneha ka 640×640mm le 740×740mm.

2. Moralo oa planifter o entsoe ka tšepe e hatelitsoeng, ha mabota a mabokose a ka hare a fanoa ka tšepe e sa hloekang.Boima bo feto-fetohang bo behiloe ka mefuta e khethehileng ea SKF (Sweden) e ikemetseng ea mela e habeli.

3. Liforeimi tsa sieve li entsoe ka lepolanka le tsoang linaheng tse ling tseo ka hare le ka ntle li koahetsoeng ka polasetiki ea melamine lamination.Li ka theoleloa 'me li ka fetoha.Liforeimi tsa sieve li na le literei tsa tšepe tse sa hloekang.Karolo e 'ngoe le e' ngoe kaofela e tlanngoe ka foreimi ea tšepe le li-screws tsa khatello ea micrometric ho tloha holimo.Ho bonolo ebile ho potlakile ho fetola leano la ho sefa la planifter ha ho hlokahala.

4. Lits'oants'o tsa ho ntša metsi tsa sesebelisoa sena sa ho sefa phofo li tla le likatiba tsa polasetiki tse ntšo ka har'a sekhahla sa matla a khoheli.

5. Lisefa tsa SEFAR lia amoheloa.

6. Li-sieve tsa NOVA le tsona li teng bakeng sa planifter.Sesefo sa eona sa ka hare sa aluminium se ka finyella litlhoko tse phahameng tsa tsamaiso ea likhoerekhoere, 'me sebaka sa eona se seholo sa bolting le sebopeho sa saense se ka fana ka ts'ebetso e ntle ea sieving sebakeng se lekanyelitsoeng.

7. Likarolo tsohle tse kopanang le thepa ka ho toba li entsoe ka tšepe e sa hloekang kapa lisebelisoa tse ling tsa boleng, ho netefatsa tekanyo e kholo ea bohloeki.

8. Planifter ea rona e tla le sebopeho sa modular ho latela litlhoko tsa hau.E fumaneha ka mekhahlelo e mene ea planifter, planifter ea likarolo tse tšeletseng le planifter ea likarolo tse robeli, e le hore u ka etsa boholo ba sebaka se teng.

9. Lerako le ka hare le monyako li tla le mekhoa e tsoetseng pele ea ho kenya mocheso oa mocheso, ho qoba linyeoe tsa condensation ea mongobo ka tekanyo e kholo.

Lethathamo la Mekhahlelo ea Teknoloji

| Mofuta | Likarolo | Sieve Height (mm) | Sieve Frame Height | Bophahamo bo Bonyane ba ho Kenyeha | Matla | Rotary Diameter | Lebelo le ka Sehloohong la Shaft | Sebaka sa ho Sefa | Boima ba 'mele | ||||||||

| 640 | 740 | 640 | 740 | 640 | 740 | 640 | 740 | 640 | 740 | 640 | 740 | 640 | 740 | 640 | 740 | ||

| FSFG4×16 | 4 | 1800 | 1720 | 2800 | 3 | 3 | 64±2 | 245 | 21.1 | 29.1 | 2550 | 2900 | |||||

| FSFG6×16 | 6 | 1800 | 1720 | 2800 | 4 | 5.5 | 31.7 | 43.7 | 2800 | 3150 | |||||||

| FSFG8×16 | 8 | 1800 | 1720 | 2800 | 5.5 | 7.5 | 42.2 | 58.2 | 3200 | 3500 | |||||||

| FSFG4×24 | 4 | 2200 | 2300 | 1950 | 2050 | 3200 | 3300 | 3 | 5.5 | 31.7 | 43.7 | 2900 | 3700 | ||||

| FSFG6×24 | 6 | 2200 | 2300 | 1950 | 2050 | 3200 | 3300 | 4 | 7.5 | 47.5 | 65.5 | 3550 | 4550 | ||||

| FSFG8×24 | 8 | 2200 | 2300 | 1950 | 2050 | 3200 | 3300 | 7.5 | 11 | 63.4 | 87.4 | 4700 | 5300 | ||||

| FSFG4×28 | 4 | 2470 | 2180 | 3540 | 4 | 7.5 | 37 | 51 | 3350 | 3950 | |||||||

| FSFG6×28 | 6 | 2470 | 2180 | 3540 | 5.5 | 7.5 | 55.4 | 76.4 | 4100 | 4900 | |||||||

| FSFG8×28 | 8 | 2470 | 2180 | 3540 | 11 | 15 | 73.9 | 101.9 | 5200 | 6200 | |||||||

Lintlha tsa Sehlahisoa

Sieve foreimi le mochini oa phetisetso: Moralo o ikhethileng oa ho kopanngoa ha foreimi ea mantlha le li-partitions ka sebopeho se seholo, 'me thepa e nka koloi e tlase ea alloy.

Kholomo ea foreimi ea sieve: kholomo ea foreimi ea sieve e nka phala ea tšepe e se nang sebopeho e se nang seamless, e sebelisa sebopeho sa khokahano ea mortise-tenon lipakeng tsa bokaholimo le poleiti e tlase.

Sekhahla sa sieve: Sekhahla sa lepolanka sa sieve, se koahetsoeng ka polasetiki, se sa sebetse, se thibela ho senyeha ha mongobo, likhutlo tse koahetsoeng ka tšepe bakeng sa boima bo matla, boholo bo loketseng, phapanyetsano e bonolo.Mochine oa ho notlela khatello ea maikutlo o bonolo ebile o ka tšeptjoa, mosebetsi o motle holim'a foreime o qoba ho tsoa ha phofo.

Lisebelisoa tsa sieve le li-tray cleaners:

Lihloeki tsa sieve li ka thibela ho thijoa ha sieve, 'me lihloekisi tsa literei li ka sututsa thepa hore e tsamaee hantle.

Fiber khalase lintho tse bonahalang suspender.

Mabapi le rona