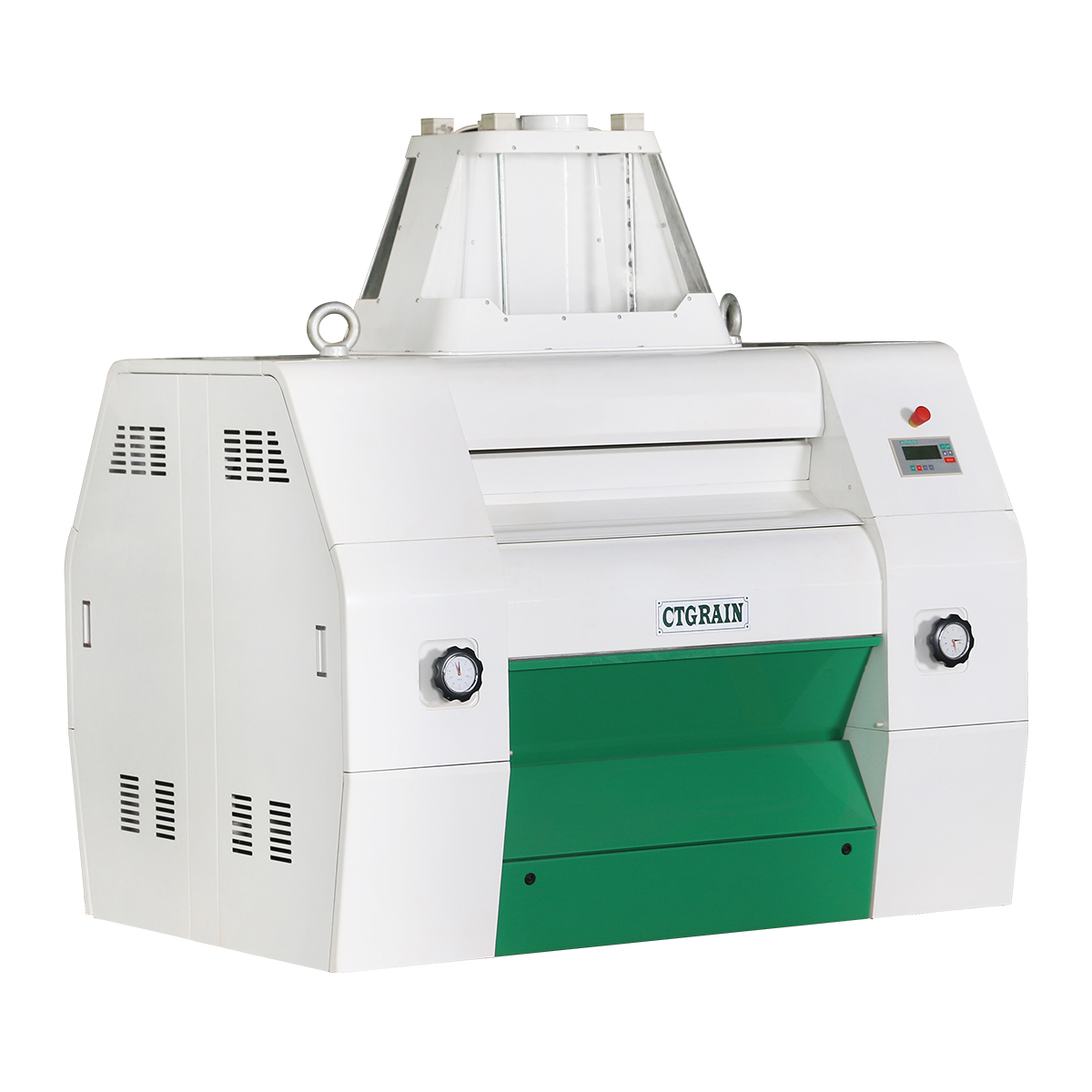

Leloala la Motlakase oa Koro Poone

Mochini oa ho sila lijo-thollo

E sebelisoa haholo ho Flour Mill, Corn Mill, Feed Mill joalo-joalo.

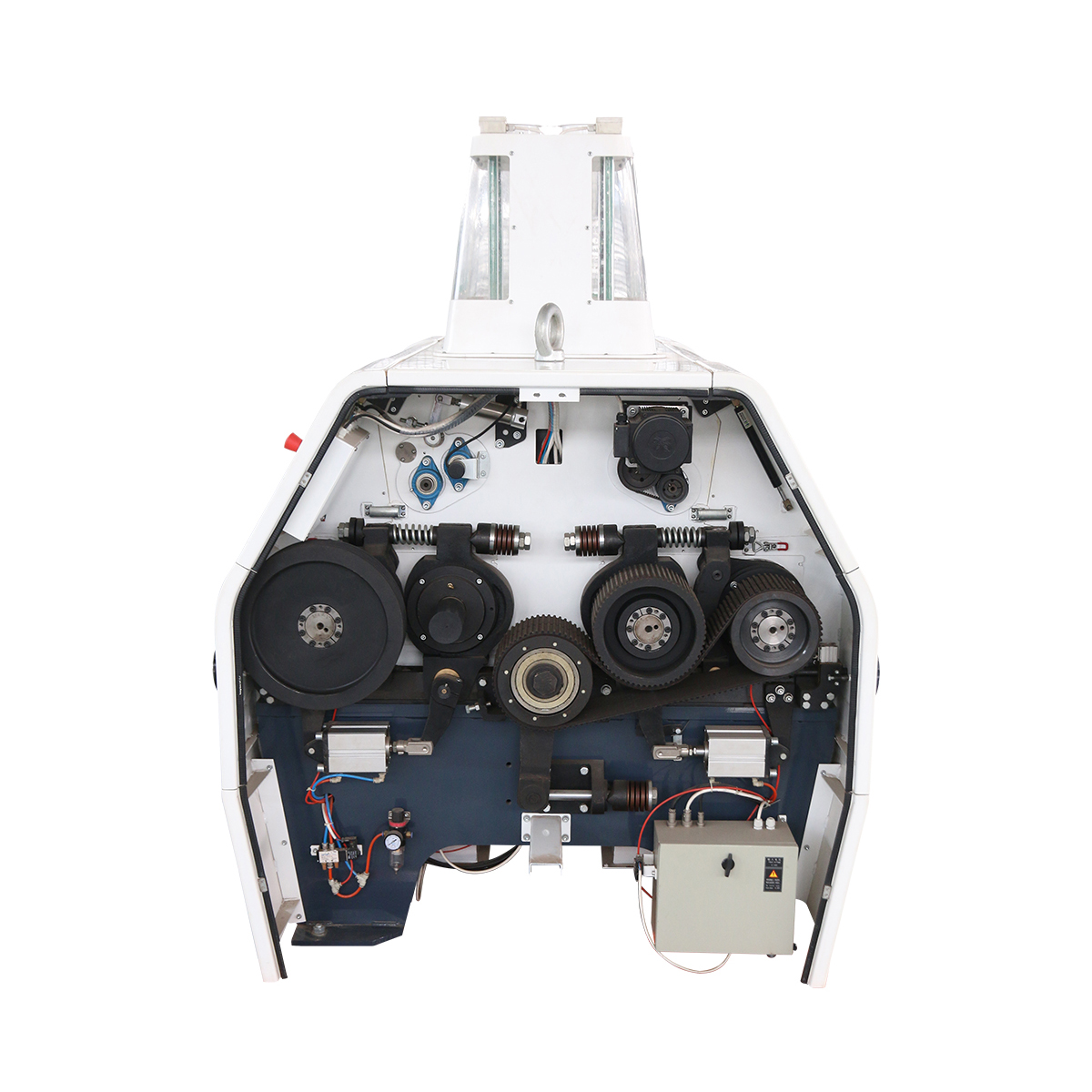

Molao-motheo oa ho sebetsa

Ka mor'a hore mochine o qale, li-roller li qala ho potoloha.Sebaka sa lirolara tse peli se sephara.Nakong ena, ha ho na lintho tse kenngoeng ka har'a mochini ho tsoa ho inlet.Ha ho kopaneloa, rolara e liehang e fetela ho roller e potlakileng ka tloaelo, ho sa le joalo, mokhoa oa ho fepa o qala ho fepa lintho tse bonahalang.Ka nako ena, likarolo tse amanang le mochini oa ho fepa le mochini oa ho lokisa lekhalo la lirolara li qala ho sisinyeha.Haeba sebaka sa li-roller tse peli se lekana le lekhalo la ho sebetsa, li-roller tse peli li kopanela 'me li qala ho sila ka mokhoa o tloaelehileng.Ha o itšehla thajana, motho ea liehang ho tsamaea o tloha ho tloha ka potlako, ho sa le joalo, mochine oa ho fepa o emisa ho fepa lintho tse bonahalang.Mokhoa oa ho fepa o etsa hore thepa e phalle ka kamoreng ea ho sila ka mokhoa o tsitsitseng 'me e hasanya thepa ka bophara ba ho sebetsa ka mokhoa o ts'oanang.Boemo ba ho sebetsa ba mokhoa oa ho fepa bo lumellana le boemo ba ho sebetsa ba rolara, thepa ea ho fepa kapa thepa ea ho emisa e ka laoloa ke mochine oa ho fepa.Mokhoa oa ho fepa o ka fetola sekhahla sa phepelo ka bohona ho latela bongata ba thepa ea ho fepa.

Likaroloana

1) Roller e entsoe ka tšepe ea centrifugal, e leka-lekaneng ka nako e telele ea ho sebetsa.

2) Tlhophiso e otlolohileng ea roller le servo-feeder e kenya letsoho ts'ebetsong e phethahetseng ea ho sila.

3) Moralo oa takatso ea moea bakeng sa lekhalo la lirolara o thusa ho fokotsa mocheso oa mochini o silang.

4) Sistimi ea opereishene ea othomathike e etsa hore ho khonehe ho bonts'a kapa ho fetola paramente habonolo haholo.

5) Lisebelisoa tsohle tsa lirolara li ka laoloa ka bohareng (mohlala, ho ts'oaroa / ho tlosoa) ka sistimi ea PLC le setsing sa taolo.

Lethathamo la Mekhahlelo ea Teknoloji

| Mofuta/Paramethara | Bolelele | Diameter | Ho fepa Motor | Boima ba 'mele | Boholo ba Sebopeho |

| mm | mm | kw | kg | LxWxH(mm) | |

| MME80x25x2 | 800 | 250 | 0.37 | 2850 | 1610x1526x1955 |

| MME100x25x2 | 1000 | 250 | 0.37 | 3250 | 1810x1526x1955 |

| MME100x30x2 | 1000 | 300 | 0.37 | 3950 | 1810x1676x2005 |

| MME125x30x2 | 1250 | 300 | 0.37 | 4650 | 2060x1676x2005 |

Lintlha tsa Sehlahisoa

Level Sensor: Sensor ea boemo e laoloa ke infrared.Taolo e matla ea phallo, phepelo e nepahetseng ea lirolara tsa phepelo qoba ho kenella khafetsa le ho lahla rolara le ho lelefatsa bophelo ba tšebeletso ea rolara.

Roller: Ho lahla ha tšepe habeli, matla a phahameng, le ho hanyetsa ho apara hantle.Ho se leka-lekane ha tekanyo e matla ≤ 2g.Kakaretso ea radial e felile<0.008 limilimithara.Sephetho sa shaft se tšoaroa ka 40Cr mme boima ke HB248-286.Ho thatafala ha sefahleho sa rolara: Rolara e boreleli ke Hs62-68, leino ke Hs72-78.Ntle ho moo, kabo ea boima bo tšoana, 'me phapang ea boima ba rolara ke ≤ Hs4.Bophelo bo bolelele ba tšebeletso.

Roller Gap Adjusting: Ho fetoha ha lekhalo le bonahalang, ho sebetsa habonolo

Transmission Spring Tensioning Mechanism: Mokhoa oa phetisetso oa phetisetso ea selemo o ka netefatsa hore lebanta la wedge le fetisoa ka mokhoa o tsitsitseng ka lerata le tlase le bophelo bo bolelele ba ts'ebeletso.

Mabapi le rona